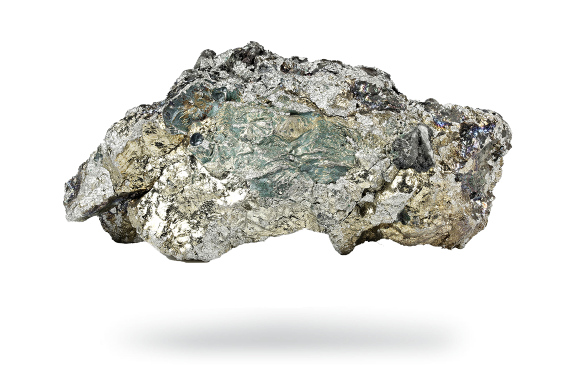

Cobalt

Cobalt minerals have been used as pigments since ancient times. In the 15th century, miners in the Ore Mountains (Erzgebirge) in central Europe used the term kobold for certain ores that were difficult to smelt and which, when roasted, produced toxic smokes.

When melted together with sand, these roasted ores were converted into a blue glass called smalt. In 1742 the Swedish chemist Brandt showed that this colour was due to an unknown metallic element, which was isolated in 1780 by Bergman. The pottery and ceramic industries were the only consumers of cobalt up to the beginning of the 20th century.

Properties

- A bluish-grey metal, similar to iron and nickel.

- Ferromagnetic (Curie point, 1121°C).

- Crystallises at room temperature in the close-packed hexagonal system (α–Co) and converts to the face-centred cubic form (β–Co) at 417°C.

Applications

- Cobalt compounds and cobalt oxide are respectively used as catalysts and in the petroleum industry.

- Organic carboxylate salts of cobalt are used as driers in paints, varnishes and inks.

- Other organic derivatives, such as the stearates, have found applications in the rubber industry to promote adherence to metallic reinforcements, e.g. in the making of radial corded tyres and rubber conveyors.

- Cobalt also has a very broad application in rechargeable batteries, mainly of the NiMH and Li-ion type. The incorporation of cobalt in the form of powder or hydroxide improves the electrochemical characteristics of these batteries.

Recycling

Much of the cobalt is recovered from the production processes of manufacturers of applications like hard metal and cemented carbide tools or NiMH and Li-ion rechargeable batteries. Cobalt can also be recovered from end-of-life products such as spent rechargeable batteries, petrochemical catalysts and alloys used in aerospace applications.